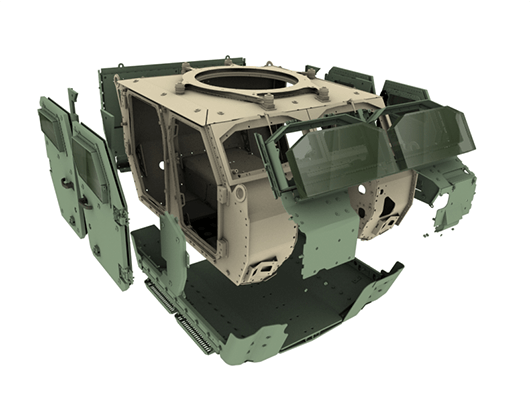

Kitted Hull

High-end protection. Low operating cost.

The Kitted Hull is designed to provide high-end vehicle protection in a cost-effective way. It is a unique concept, which introduces a design and production process for weld-free assembly armored cabin. Utilizing Kitted Hulls vehicles protection is assembled with bolted & bonded kits. Plasan’s Kitted Hull solution is battle proven for over 10 years with thousands of vehicles deployed.

WHY SELECT PLASAN’S KITTED HULL

Cost-effectiveness

Lower cost of work thanks to simple assembly process which does not require expert welding. Easier to upgrade armor parts on existing platforms

Rapid Assembly

Component parts are easily consigned to qualified subcontractors for fast assembly on customer site

Easy Repair

The process of replacing/fixing armor parts of the kitted hull after an incident (fire or IED) is straightforward and simple to be carried out by the end-user.

High quality

Based on Plasan’s materials expertise, kit components are designed with the material composition that aims to achieve optimal performance-weight balance.

Tailor-made

As bolted parts may be assembled together from a variety of materials and material thicknesses, vehicle protection can be tailor designed per threat level and mission environments.

Logistic Footprint

Kitted hulls offer higher usability of vehicles/fleet. Kit components may be easily replaced and repaired, so that there is no need to have an entire mission-ready fleet at all times.

BLAST MANAGEMENT

The kitted hull, being a bolted armour kit, is more flexible than a welded hull, and is not subject to the same structural constraints/tensions. This represents an advantage when confronting a blast.

Segmenting the hull’s surface into chosen sections/areas allows to predict and select failure points, and to have better control over the blast management. Kitted hull design also allows better control of secondary projectiles during a blast event.

BALLISTIC PROTECTION

The composite armor of Plasan’s kitted hull is based on Metal Composite and/or Ceramic Composite armor panels. Spall liners, which are used to provide improved protection by significantly reducing the lethality of fragments evolving from an overmatch, can be easily incorporated into the vehicle basic structure.

QUICK DEVELOPMENT

The design and development process of the kitted hull cabin is relatively short. Due to the minimum tooling required, fast prototyping is natural. This in turn cuts down development costs.