pultrusion

OUR CAPABILITIES

PNA has the Pultrusion know-how, capabilities and equipment to solve your composite part manufacturing challenges. We have the ancillary lab equipment needed to support testing required to verify parameters such as resin reactivity and viscosity as well as to perform tensile and bend strength tests for finished pultruded products. Utilizing our experienced operators, engineering expertise and ultra-high quality standards, Plasan provides tooling, process definition, die design and material selections for your specific pultrusion needs.

the benefits of pultrusion

Lowest Cost Process for constant cross-section structural composites

- At least 50% less expensive than VARTM for making composite structures

- Savings independently verified in a Northrop Grumman cost study for a large glass marine composite structure previously produced

- Pultruded composites are cost competitive with the steel systems they replace

Pultruded Products

Stanchions

Missile Canisters

Vehicle Body Panels

Spall Liners

Pultrusion 101

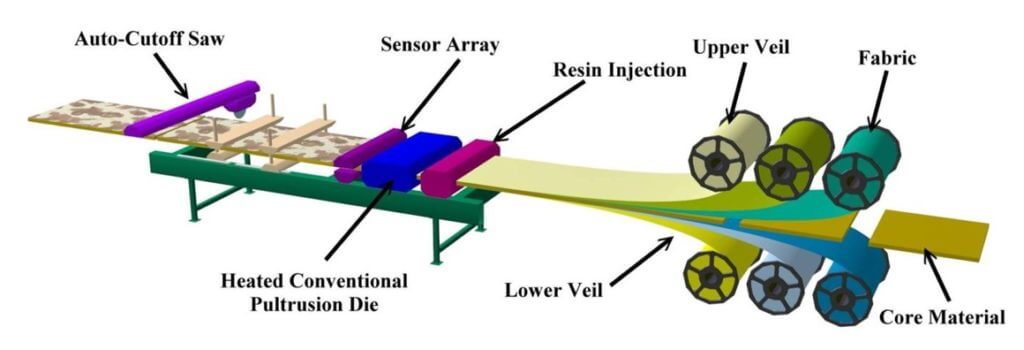

Reinforcement materials like fibers or fabrics are impregnated with resin and pulled through a heated stationary die where the resin undergoes polymerization. The impregnation is either done by pulling the reinforcement through a bath or by injecting the resin into an injection chamber which typically is connected to the die. A veil is added to protect against erosion and provide corrosion and ultraviolet resistance.