Plasan North America says it can help the Army with its ever-increasing struggle to get electricity to the battlefield.

The U.S. Army’s rapid adoption of new Soldier-worn devices, C5ISR systems and networked sensors is touted as “transformative”. But the Army has not addressed the infrastructure or “back-end” needed to keep them powered-up with electricity.

Without the capacity to efficiently store and distribute electricity near or at the tactical edge, the Army will struggle to realize the potential of its new tools. Plasan North America (PNA) has been thinking through the challenge of storing electrical energy and getting it to the front lines since 2015.

Plasan NA supplies high performance aramid, composite, and metal components to Tier 1 defense vendors and the U.S. military. The company is used to looking across technical ecosystems, visualizing its own role therein and how other elements collectively function. That awareness led its leadership to identify a problem it calls Battlefield Circulation of Electricity (BCoE).

“It feels like the individual Army requirements offices are still rather stove-piped in requirements development,” PNA president, John Cavedo, says. “More and more systems and devices are being fielded which require electricity from a battery, but there doesn’t seem to be an enterprise-level analysis being done to address the impact on the force to supply the electricity at the tactical edge.”

An Army Futures Command (AFC) spokesperson says its Futures and Concepts Center is developing an Army Operational Energy Strategy which will be published late this year. But the precise details of how much energy will/can be delivered in multi-domain operations, “through which mechanisms and how quickly, are still to be determined,” AFC acknowledges. Investing in technologies “that can provide exportable power forward” is one of its priorities.

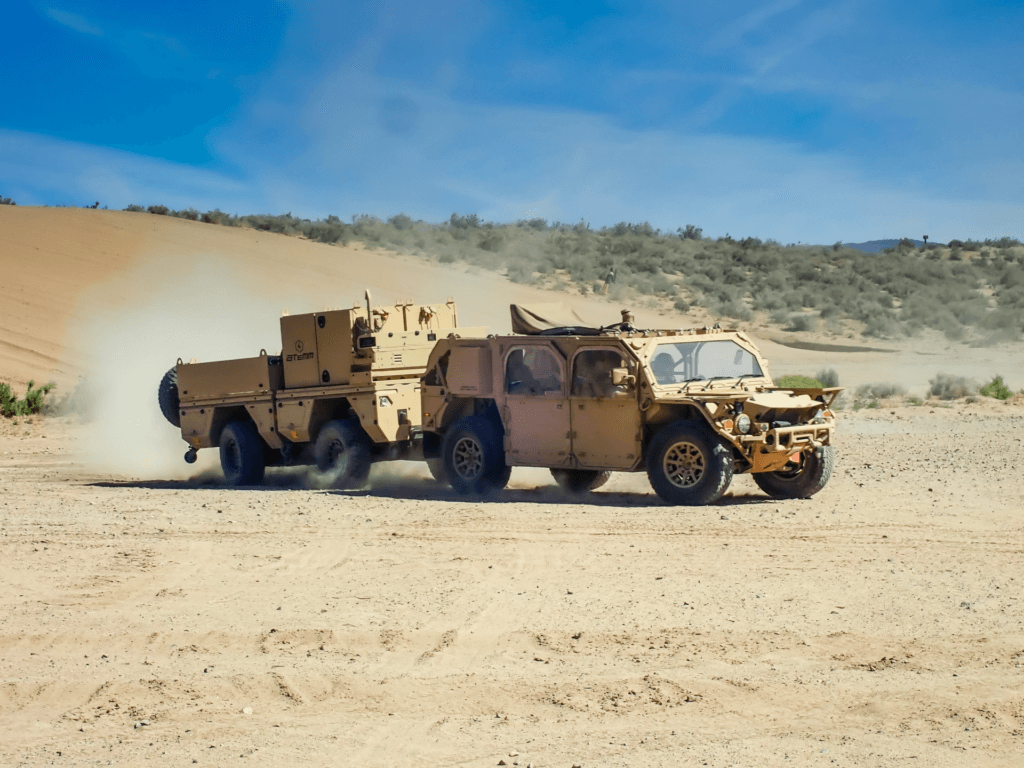

The All-Terrain Electric Mission Module (ATeMM, pronounced “atom”) is Plasan’s answer to providing exportable power forward – a modular self-propelled, self-charging 47-plus kilowatt-hour DC battery trailer which can be towed or dispatched via remote control to the front lines where it can store and export electricity.

The company calls it a “multi-tool”, capable of filling gaps that towed generators, towed trailers and power distribution boxes cannot.

Battlefield Circulation of Electricity

Photo: Courtesy of Plasan North America

The Army’s first Climate Strategy document, released earlier this year, envisions broad-based electrification, ultimately including EVs. To provide energy, it repeatedly mentions the need for microgrids underpinned by renewable electricity generation and battery storage. These will theoretically bridge the battlefield power gap.

Army support elements including mobile command posts currently supply combat formations with electrical power using “spot generation” – towing trailer mounted tactical generators behind HUMVEEs, JLTVs FMTVs and other wheeled vehicles. A single generator or generators running in parallel service the tactical electricity load. But with little electricity storage available, generators run continuously to provide instant power burning copious quantities of fuel.

The command posts the Army and Marines use typically consume a considerable amount of fuel per day to move as well as generate electrical power. The power supplied to sensors/systems via towed generators varies to meet a range of tactical imperatives How much fuel and how much electrical power do command posts consume on average? It’s not a figure the Army has readily available. While generators can supply power, they can’t store surplus electricity.

The scarcity of storage could impact new Soldier systems like IVAS (Integrated Visual Augmentation System) smart goggles. It’s estimated that a Soldier in an Infantry Brigade Combat Team (IBCT) platoon will consume three conformal wearable batteries (CWBs) every 24 hours to power them. A 40-man platoon would likely consume 120 batteries in a 24 hour period. This doesn’t include other battery powered systems like radios or drones.

An entire IBCT could theoretically consume 8,000 CWBs every 24 hours to feed these devices, requiring 16,000 CWBs in circulation (8,000 with Soldiers, 8,000 being charged/swapped for daily logistics packs). In large mobile combat operations, the Army’s currently fielded Universal Battery Chargers (or even new Advanced Battery Chargers) will unlikely be able to meet this demand.

“If you talk to people at PEO Soldier or Soldiers in the IBCT,” Cavedo says, “I am sure they would tell you they will be severely challenged to operate their battery-powered systems like IVAS because they lack the ability to move stored electricity at the rate and volume needed across the battlefield to meet the ever-growing demand, especially during continuous operations of 72 to 96 hours.”

Despite looking at other options from man-packable platoon power generators for dismounted soldiers to a hybrid power trailer that couples a 15 kW quiet generator with an 80 kilowatt-hour lithium-ion battery, the service has yet to find a single solution for filling an electrical power gap.

In July, the Army assessed yet another approach to BCoE, a concept called Secure Tactical Advanced Mobile Power (STAMP) – a lightweight hybrid power system that allows multiple vehicles to network their electrical systems together, sharing power generation in a small electrical grid. Aggregating multiple vehicles with onboard power generation and electrical power output could generate fuel savings, allowing support elements to deploy fewer tactical generators.

It’s an interesting idea but it doesn’t address the possibility of storing generated electrical power. In field tests like the 2022 Army Expeditionary Warrior Experiment at Fort Benning, PNA has demonstrated that ATeMM can provide on-demand electricity storage and export, helping meet the BCoE demands the Army and Marines are facing.

Photo: Courtesy of Plasan North America

Filling Gaps, Easing The Burden – ATeMM

In short, the ATeMM can;

- Provide electric storage capacity to meet demand

- Reduce fuel consumption and the fuel logistics burden

- Reduce generator requirements/maintenance

- Enhance Mobility, going where conventional trailers can’t with its own tractive power

- Provide 20 kW of export power while stationary or on the move

Currently deployed microgrids run a minimum two generators, one supplying power for the main load while another idles in “spinning reserve” capacity. At best, they convert fuel to electricity at 35 percent thermal efficiency, losing much of the fuel energy as heat/exhaust in the process. (An idling reserve generator makes no appreciable contribution yet burns fuel to maintain its reserve status.)

ATeMM offers the opportunity to harvest and store excess electricity from generators, silently supplying instantaneous surge power (47 kWh) with efficiency in the high 90 percent range. As a result, microgrid generators could run less, easing fuel, logistics and maintenance support burdens.

With 20 kW of exportable power, ATeMM mission variants can serve system or Soldier needs, feeding power to communications gear or acting as battery recharging stations. For example, a group of 10 dismounted soldiers consumes a total of 4.5 kWh power from their CWBs per day. Once spent, their batteries go back in their rucksacks adding dead-weight and fatigue.

“One ATeMM,” Cavedo says, “used as a stationary recharge point and CWB-drop would be able to replenish [batteries] for about 100 Soldiers over a 24 hour period.”

The platform features a 200kW (217 hp) traction motor generating 5700Nm (750 ft-lb) of torque at its single axle. Its battery pack provides power to the motor and off-board vehicle power. It can recover exported power as it is towed using a familiar regenerative coast/braking strategy to charge the battery.

ATeMM effectively turns a traditional combustion-engined 4X4 lead vehicle into a hybrid 6X6, increasing its mobility while enabling it to operate in full electric (Silent Watch) stationary or mobile modes, decreasing its acoustic and thermal signatures. Its synchronized steering and braking capability enhances maneuverability and ease of operation for lead-vehicle drivers.

As a trailer, ATeMM also offers 2,500 lbs (1,150 kg) of payload with the opportunity to both carry and power drones, batteries, sensors, or weapons systems. Its modular architecture supports a wide range of battery and motor options with room for growth or reallocation of space as battery size, weight and power improve.

On the move, ATeMM’s additive power reduces vehicle-trailer carbon emissions and logistics demands compared with towed generators or towed battery trailers. “If you put a big generator behind a HUMVEE and you try to take it offroad, you’re going to feel it,” ATeMM Lead Engineer, Dan Jakiela affirms. “An ATeMM can push the lead vehicle. You’re enhancing your mobility and capability while decreasing your overall fuel consumption.”

The ATeMM’s modular design allows for two units to be rigidly connected and synchronized as a tandem “ATeMM-T”. The tandem increases battery capacity to over 94 kWh and offers 5000 lbs (2,300 kg) total payload. A connected leading vehicle (HUMVEE, JLTV or ISV) becomes an 8X8 hybrid with different drive modes, payloads and power export options.

The ATeMM-T offers tantalizing possibilities for remote-control robotic dispatch to the tactical edge, rendezvousing with mechanized or dismounted elements to supply power, exchange batteries, evacuate wounded or provide ISR drones.

“We integrated an ATeMM with a GMV1.1 back in June as a technology demonstrator,” Lt.Col Alfredo Romero (USMC), Program Manager for SOCOM’s Family of Special Operations Vehicles acknowledges. “There are endless possibilities with the ATeMM from its ability to trailer and form a hybrid-electric vehicle with increased payload to an autonomous platform that can integrate lethality and CUAS. If we are to continue down this path of electrification, we need solutions to ensure our teams have sustainable power on and off the field.”

Plasan is targeting a production price of approximately $100,000 for a base ATeMM. That compares favorably with the cost of the Army’s new SMET, and considering ATeMM’s capability, with costs for 30 kWh generators, standard JTLV trailers or other hybrid power trailers.

Crucially, ATeMM doesn’t have to await future Army infrastructure development. It can plug-into the formations/vehicles the Army deploys now, offering a valuable hybrid step to a fully electrified battlefield.

“If the Army has DC energy stored in ATeMM batteries,” John Cavedo observes, “it can get the most out of every gallon of fuel. It’s not about doing away with consuming JP-8. It’s about BCoE, reducing the amount of fuel consumed, the number of fuel convoys and the logistics burden – giving battlefield commanders flexibility and options.”

View original article on Breaking Defense here.